PVD-Consumables - E-Beam Crucibles

Summit-Tech provides E-Beam crucibles and formed cones which fit directly into the E-Beam source crucible. Both the crucibles and cones are available in a variety of materials.

Crucibles are recommended for many E-Beam evaporation processes because they:

Increase the evaporation rate to reduce cycle time and improve throughput

Enable quick material changes to minimize chamber downtime

Improve thermal stability and reduce heat transfer to the crucible

Reduce power requirements and lower the cost of ownership

Available Crucible Materials

Summit-Tech provides crucibles in 14 different materials. These include:

Graphite (C )

Molybdenum (Mo)

Aluminum oxide (Al2O3)

Zirconium oxide (ZrO2)

Vitreous carbon (Glassy-Coated Carbon)

Boron nitride (BN)

Intermetallic (BN/TiB2)

Tungsten (W)

Quartz (SiO2)

Zirconium (Zr)

Tantalum (Ta)

Copper (Cu)

PBN

Titanium carbide (TiC)

Graphite Crucibles

Materials evaporated from graphite crucibles:

Al-Ge alloys, Al-Si alloys, B, Be, Bi, CdS, CeO2, Cr, Cu, Ge, In, Mg, Mo, Na3AlF6, Pd, Pt, Sb, SiO, SiO2, Sr, Ta, Ti, Y2O3, Zn

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Pocket Volume

(cc)

4

7

N/A

40

40

N/A

40

40

30

30

156

15

15

N/A

N/A

25

62

16

1

2

3

4

7

12

25

30

100

25

25

30

40

4

20

12

1

10

NA

NA

Liner Volume

(cc)

1.8

4.4

2.4

30.4

17

126

30.2

16.9

20.2

10.3

94.7

8.2

3.9

27.1

16.2

17.1

47.6

14.7

0.32

0.84

1.44

2.1

3.7

8.3

16.3

21.9

82.7

12.8

14

18.5

27

1.6

14.6

5.6

0.24

4.8

2.8

2.3

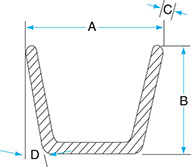

Dim A

(in.)

0.865

1.167

0.936

2.03

2.03

2.96

2

2

1.775

1.775

3.25

1.48

1.48

2.39

1.89

1.85

2.212

1.64

0.56

0.706

0.805

0.885

1.125

1.28

1.633

1.92

2.7

1.85

1.633

1.775

2.03

0.846

1.673

1.35

0.75

1.384

0.781

0.75

Dim B

(in.)

0.563

0.563

0.593

1.02

1.02

1.562

1.062

1.062

0.94

0.94

1.53

0.67

0.67

1

0.7

0.68

1.4

0.97

0.384

0.465

0.545

0.595

0.52

0.94

0.94

0.81

1.49

0.68

0.94

0.94

1.02

0.689

0.748

0.68

0.162

0.593

0.437

0.312

Dim C

(in.)

0.093

0.093

0.093

0.093

0.25

0.093

0.093

0.25

0.093

0.25

0.25

0.125

0.25

0.25

0.125

0.093

0.093

0.125

0.093

0.093

0.093

0.093

0.093

0.093

0.093

0.093

0.093

0.125

0.125

0.125

0.125

0.093

0.093

0.125

0.04

0.093

0.062

0.75

Angle D

15°

15°

15°

15°

15°

7.5°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

15°

30°

15°

14°

0°

Pyrolytic Boron Nitride (PBN) Crucibles

Our high temperature Chemical Vapor Deposition (CVD) process yields intrinsically pure Pyrolytic Boron Nitride (PBN). Performance PBN is the ideal choice for furnace, electrical, microwave, and semiconductor components

Pyrolytic Boron Nitride

Performance PBN's properties, its intrinsic purity, superior mechanical strength,

and thermal stability make it a superb choice for high temperature furnace and

electrical components; microwave and semiconductor components; and industry

standardized crucibles for gallium arsenide crystal (GAN) production.

Other properties featured in our Performance PBN include:

Good thermal conductivity

High insulation resistance

High dielectric strength over wide temperature ranges.

Extremely pure

Non-wetting

Non-toxic

Non-reactive to most other compounds

Withstands high temperatures and rapid cooling

Performance PBN will not react with acids, alkalis, organic solvents, molten metals, or Graphite. Bulk impurity levels are less than 100 parts per million with metallic impurities less than 10 parts per million. It withstands 1800° C in vacuum and 2000° C in nitrogen, showing no melting point, making it an excellent choice for furnace components and melting vessels. Crucibles heated to 1200°C can be plunged into liquid nitrogen without visible damage. PBN-coated graphite heating elements provide extremely uniform temperature profiles for both compound and silicon semiconductor manufacturing.

The anisotropic conductivity of Performance PBN improves process performance for crystal growth, whether the growth method is Liquid Encapsulated Czochralski (LEC), Vertical Gradient Freeze (VGF), or Bridgman. The high purity and physical stability of this unique material also make it the best choice for auxiliary effusion cell hardware use.

For more information on our Pyrolytic Boron Nitride material, contact us today.

Aluminum Oxide Crucibles (Al2O3)

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications.

The Summit-Tech Company is an ISO:9001-2008 certified company. Copyright ©1996-2016 Summit-Tech Company® All rights reserved.